When it comes to scaling your business, automation is key to success. At SPI Automation, we offer several customized solutions that will help you automate your systems and processes, allowing you to revolutionize your business and reach new heights. SPI Automation has been a leader in automated baking innovation for over twenty years.

This blog post will explore how our robotic muffin depanners will help you scale your business by maximizing efficiency and quality.

How Do I Depan Muffins?

As baked goods manufacturers begin to scale, one problem they face is how to depan large quantities of muffins safely and efficiently without compromising the quality of the baked goods.

This is where SPI Automation steps in with our baking automation solutions. Baking automation is a cutting-edge way to increase product quality while increasing revenue.

One of the ways SPI Automation is helping businesses scale and succeed is through the robotic muffin depanning machine. The integration of automation is specifically helpful for muffin depanning. With each baked muffin being depanned and placed simultaneously onto adjacent packaging conveyors, the process is significantly faster and more efficient.

What is a Robotic Muffin Depanner?

A robotic muffin depanner is a machine used in industrial baking facilities to remove muffins from their baking trays or pans, a process known as depanning. The machine is designed to gently remove the muffins from their baking trays without causing any damage or deformation to the muffins. The depanned muffins are then usually conveyed to a packaging station or a cooling rack, depending on the bakery’s requirements. Depanning muffins manually can be labor-intensive and time-consuming, especially in high-volume bakeries. Many facilities use automated depanning machines to improve efficiency and productivity.

How Does a Robotic Muffin Depanner Work?

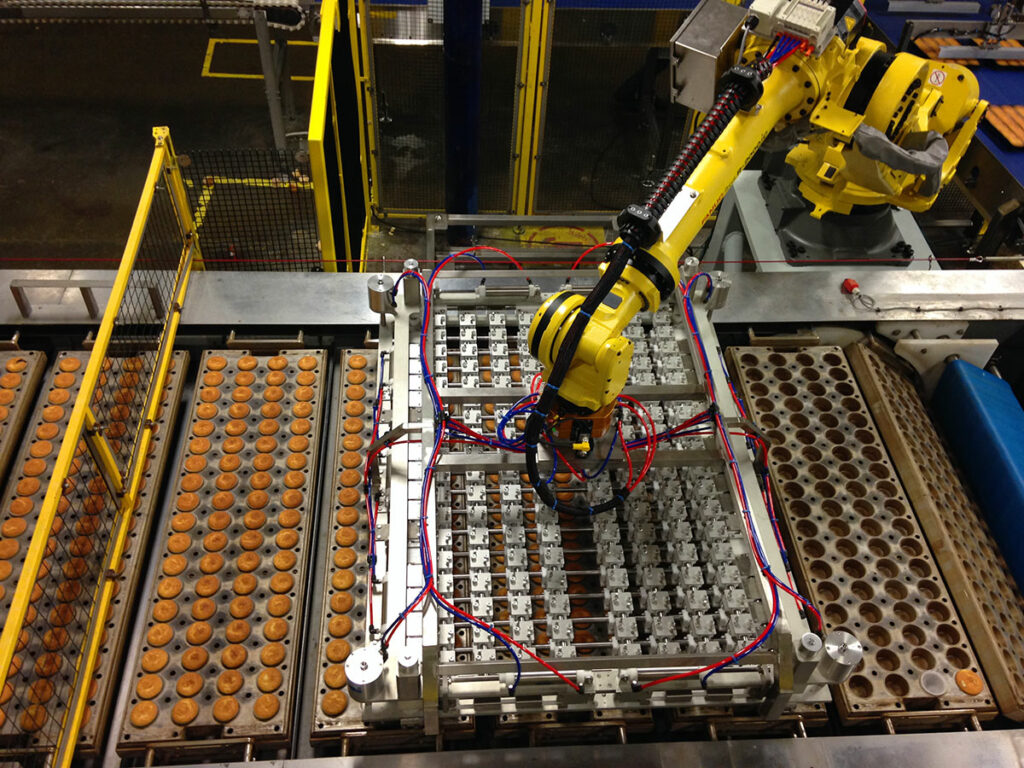

In the muffin depanning system, the process starts with the muffins being transported to the depanner on a conveyor belt. The machine then uses a specialized end-of-arm tooling (EOAT), which can be custom-made to fit exact project requirements, to pick up the muffins one by one and place them onto adjacent packaging conveyors.

The EOAT can also rearrange the position of the depanned muffins into the specific count and position needed for the packaging containers. There are typically two types of EOAT for muffin depanning: pin depanner tooling and vacuum depanner tooling. The pins or vacuum suction cups on the tooling are used to grip the muffins and lift them out of their molds or trays.

Many of our customers use the same conveyor line for multiple baked muffins to save factory floor space. One of the important features of the muffin depanning systems is the ability to quickly change the EOAT to accommodate for different shaped and sized muffins.

The entire EOAT on the machine can be changed quickly without the use of any tools or the need for a human technician to physically handle the tooling head. Each of our automated muffin depanners is equipped with a pneumatic connection ring that acts as a quick release and attachment point. EOAT changes can take place in a matter of seconds, not minutes. This Quick Change Tooling feature results in less downtime, which equals increased efficiency and revenue.

Our muffin depanning systems can depan muffins at a high rate of up to 1,200 muffins per minute, significantly faster than manual or semi-automatic systems. The use of automation in muffin depanning not only increases efficiency but also improves product quality by reducing the risk of damage or breakage during the depanning process.

What Are the Benefits of a Robotic Muffin Depanner?

Higher depanning rates: The greatest benefit of a muffin depanning system is that it can depan muffins at a high rate, up to 1,200 muffins per minute. This can significantly increase the overall output of the bakery.

Improved product quality: One fear regarding robotic muffin deppaners is that increased speed may come at the expense of the quality of the final product. But you may be surprised to discover that muffin depanners can improve the quality of muffins. Depanners are designed to gently and carefully handle muffins, reducing the risk of damage to the muffins. This results in a higher-quality product that meets the desired standards.

Custom end-of-arm tooling: Specialized end-of-arm tooling (EOAT) allows for customized manipulation of muffins, including arranging them in specific positions and counts for packaging.

Quick change tooling: Have several different products you package at your facility? The ability to quickly change the EOAT to accommodate different muffin shapes and sizes saves time and increases efficiency, resulting in less downtime and increased revenue.

Increased safety: A robotic muffin depanner creates a safer working environment. Muffin depanners eliminate the need for employees to handle hot pans to manually depan the muffins reducing the risk of burns and other injuries. In addition, muffin panners are able to reach across large, industrial-sized ovens that human workers can’t.

Is a Robotic Muffin Depanner the Right Solution For My Business?

Whether a robotic muffin depanner is the right solution for your business depends on your specific needs and production goals. A muffin depanner can be a beneficial addition to your baking process if you are looking to increase productivity, improve product quality, and reduce labor costs. Here are some factors to consider when deciding if a muffin depanner is the right choice for you:

Production Volume: If you have high production volume, an automated muffin depanner can help improve your throughput and reduce the need for manual labor. The machine can quickly and efficiently remove muffins from the trays at a faster rate than a human operator.

Product Quality: A robotic muffin depanner can help maintain consistent product quality by removing each muffin from the tray without damage or deformation. This can help reduce waste and improve customer satisfaction.

Labor Costs: Using a robotic muffin depanner can help reduce labor costs by minimizing the need for manual labor, allowing you to allocate your resources more effectively.

Customization: A robotic muffin depanner can be customized to fit your specific production needs, such as tray size and product handling requirements, providing a tailored solution for your bakery.

Why Choose SPI Automation?

An Industry Leader

SPI Automation is a leader in the automated machine industry. We have been transforming complex, labor-intensive tasks into smoothly operating automated systems for our customers for over twenty years.

Customized Solutions

We know that running a successful business today requires solutions as unique as you are. We excel at providing tailored solutions that meet your specific needs. Don’t settle for “off the shelf” or “stock” options that don’t really meet the needs of your business.

Flexibility

Maximum flexibility allows you to increase your efficiency. That’s why all of our denesters are built to handle round, square, or rectangular cups with “on the fly” capability allowing you to denest multiple products quickly.

A Partner You Can Trust

At SPI Automation, it’s not just about the job; it’s about the relationship. That’s why we approach each project as a partnership, working with you throughout the design and build process to ensure that each product is built to your exact specifications. Individual tooling is designed and matched to your specific requirements.

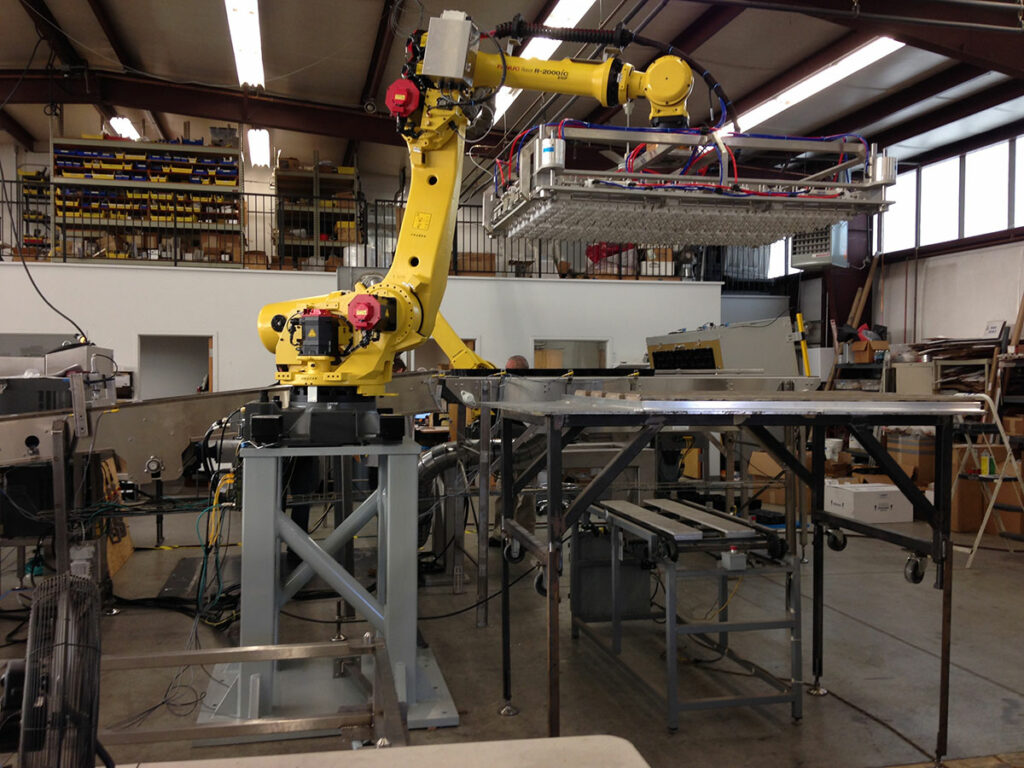

Each step of the process, from initial concept through installation at your plant, is done in-house. This allows us to ensure you receive the highest quality and customer service from start to finish.

Interested in learning more about how our muffin depanners can take your manufacturing and packaging processes to the next level? Contact us at SPI Automation today.

start a conversation

Call us at 801-233-8000 or start a conversation by filling out the form below

"*" indicates required fields