The increased efficiency and reduced labor costs automated technology brings are on the top of any business goals bucket list, but some companies worry about the commitment automation requires. Finding the right robotics integrator to provide a customized automation solution is an investment of both time and money, two resources that are critical to your business. To justify the cost of automation, many leaders and managers demand clear benefits that will impact the bottom line of the business quickly.

How do you decide if robotics process automation or RPA is worth it for your business? Before we delve into details about ROI and other metrics, let’s quantify the actual costs and benefits of automation.

What are the costs of automation?

A recent survey from Deloitte indicated more than half of their respondents had already implemented some sort of process automation with an average return on their investment in under 12 months. Today, the logic behind investing in RPA is not about the expense of automation, but the cost to your business of not automating to keep up with your competitors.

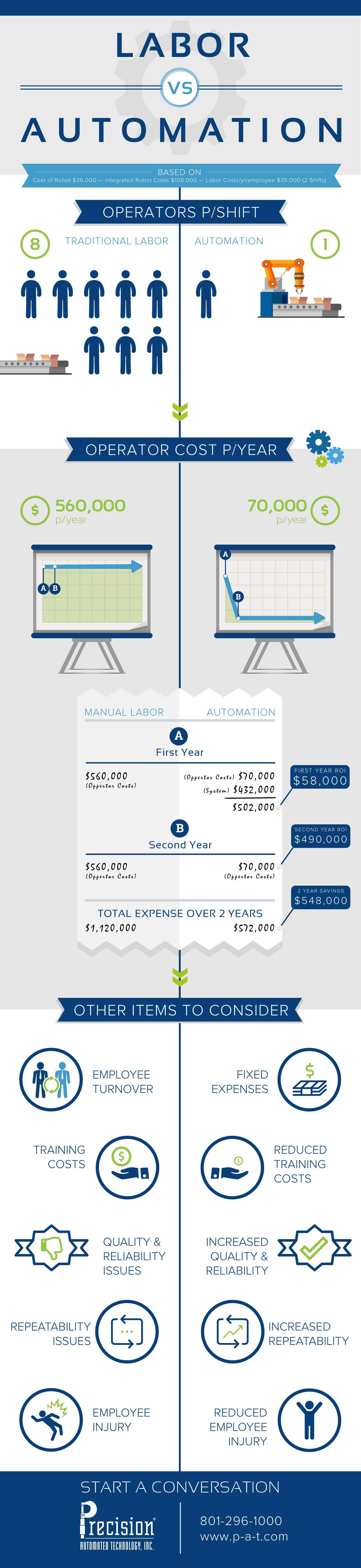

Using our example below you can see how, despite an initial investment to bring a robotics system online, the reduction in labor costs can swiftly offset the expense of both technology and the integration process.

Am I too small to automate?

This is a common question, and the short answer is absolutely not. Even small businesses can reap the benefits of automation provided they carefully analyze the right projects to address.

“One of the first responses we get when we are asked to quote an automation project, is how can I justify the expense? My company is too small. We recently met with a customer whose process involved hand decorating coffee cakes at a rate of 30,000-40,000 cakes per week. Each week they lost 20% of their production due to labor shortages and inconsistent quality. We were able to demonstrate that by introducing automation, they could increase production and quality. As we have completed the project, not only have they increased profitability, but they have also gained the flexibility of allocating labor elsewhere in their plant. Their return on investment was measured in months and not years.”

— James G. Wendler, President & CEO of SPI Automation

Justifying the costs of automation

As you attempt to balance the scales to substantiate whether a project is worth automating or not, there are several key factors to consider. Indeed, one of the very first factors is a metric we’ve already mentioned—ROI or return on investment. But the balance sheet of whether automation will work for your business shouldn’t start or end with just the tangible benefits of automation.

Carefully review and account for each of the following as you weigh a decision to invest in robotics process automation solutions.

Start but don’t stop with ROI (Return on Investment)

Return on investment is an excellent metric to provide an overview of whether your project or process is a candidate for automation, but it’s certainly not the end of the discussion. Process automation can have many intangible benefits that are hard to quantify, such as removing redundancies, improving communication, and increasing employee safety and retention. Consider the ripple effect automation might have in all sectors of your business when you’re conducting a cost-benefit analysis.

To calculate ROI yourself, visit the helpful guides below which give a thorough explanation and lead you through the equations for deducing your return on investment.

Corporate Finance Institute’s ROI formula

Consider long-term opportunities

The short-term benefits of automation often translate into the language of dollars and cents, but the long-term benefits of automating processes can be harder to articulate and quantify. Positioning yourself to outperform competitors and improving quality can be invaluable. It’s this sort of investment in long-term outcomes that can build your company’s reputation into a powerhouse and help you weather downturns in the market.

Link automation to key business objectives

When you’ve got a board to answer to or a leadership reluctant to invest, winning the argument to justify automation is more straightforward if you can show a direct link to primary business objectives. Demonstrable improvements in increasing efficiency, reducing costs, and improving safety and security all have a direct impact on profitability, so make them part of your strategy to build support for automated technology within your business or company.

Don’t forget hidden costs and benefits

Analyzing how much you’ll save in labor is a simple equation, but there are also the following hidden production costs that automation effects.

- Maintenance and service costs: Old machinery breaks down more frequently and may cost you much more in parts and service than replacing it with robotics process automation.

- Energy and sustainability: Aging systems weren’t designed to be energy efficient, and the rising cost of supplying them with power may become unsustainable over the long-term.

- Space: Making the most of the space you have gets much easier when you have customized robotics solutions that optimize your square footage. Companies able to downsize their production footprint will experience lower overhead costs.

- Data: One benefit of automation is that it can provide you detailed data to identify bottlenecks and tweak and adjust systems. This kind of insight can contribute to better efficiency across all areas of production.

SPI Automation Can Help

The goal of SPI Automation is to form a partnership. We want to understand your business, and we’re committed to helping you work through the challenges of integrating automated processes into your workflow. SPI Automation Automated Technology isn’t just a robotics integrator. We strive to be your partner in the process of bringing automation into your business, and we look forward to helping you experience the benefits of automated technology for yourself.

Need assistance justifying automation for your business? Start a conversation with SPI Automation, Inc. at 801-233-8000 or reach out to Ryan Park or Jim Wendler to see how we can help.

start a conversation

Call us at 801-233-8000 or start a conversation by filling out the form below

"*" indicates required fields